we offer innovative and advanced software solutions that cater to the unique needs of each business. Our software solutions are designed to help businesses streamline their manufacturing processes, reduce costs, and improve productivity. One of the key benefits of our software solutions is production planning. Our software allows businesses to plan their production schedules, forecast demand, and optimize inventory management. This helps businesses to ensure that they have the right materials and resources available at the right time, which in turn helps to improve efficiency and reduce waste. Another important feature of our software solutions is shop floor control. With our software, businesses can monitor production in real-time, track progress, and manage workflow. This allows businesses to identify any issues that arise during production and take corrective action immediately, which helps to reduce downtime and improve overall productivity.

We also offer quality control software solutions that help businesses maintain quality standards. Our software provides real-time data and analytics, allowing businesses to identify quality issues and take corrective action quickly. This helps businesses to maintain their reputation for high-quality products and can lead to increased customer satisfaction and loyalty. Maintenance management is another critical area where our software solutions can help businesses. Our software allows businesses to manage their maintenance operations, reducing downtime and improving overall equipment effectiveness. By ensuring that equipment is well-maintained and operating at peak efficiency, businesses can reduce maintenance costs and improve productivity. Finally, our supply chain management software solutions help businesses manage their supply chain, ensuring that they have the right materials at the right time. This helps businesses to reduce lead times and improve efficiency, which in turn can lead to increased profitability.

The client is specialized Value-add Service Provider for Semiconductor Assembly Equipment. Primarily focus on providing products to improve their customers manufacturing processes and factory performance.

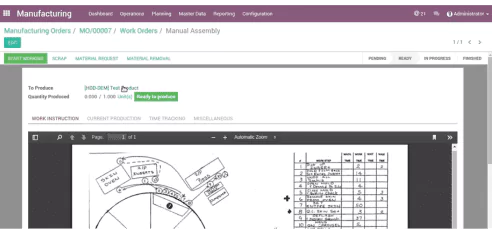

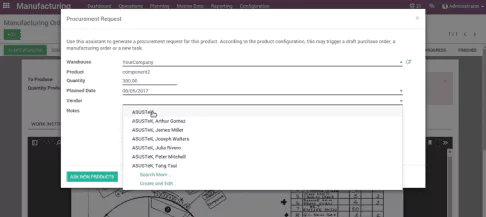

The scope of the project is to implement Odoo manufacturing module and automate the manufacturing process within the organisation.

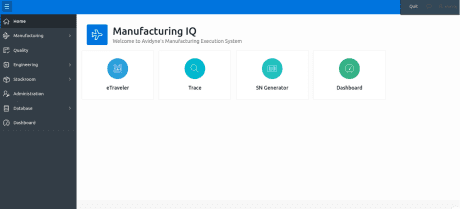

The application was developed for a US based customer who designs and manufactures integrated GPS and VHF navigation and communication systems, ADS-B In and Out transponders, active traffic systems and digital flight control systems. The ERP system was designed and implemented by Socius to automate the manufacturing process.

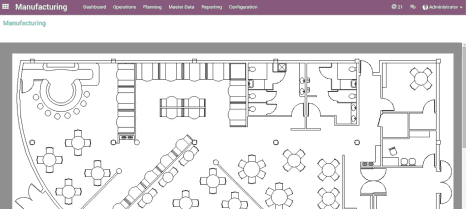

Specific Design delivers properly configured symbols, special tools and commands specific to restaurant kitchen design needs. The Scope of the project was to integrate Solidworks /CAD Systems to their ERP Platfrom.

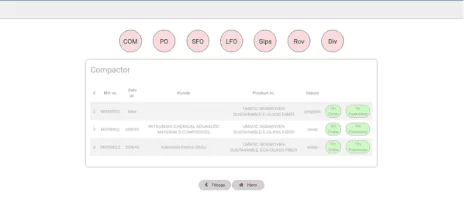

This project covers Odoo Sales, Delivery, Manufacturing and accounting part. We had changed the Odoo default Manufacturing workflow and changed default design with new design to make it more user friendly. We designed custom reports and replaced odoo default reports.

The process of managing a freight shipment involves several essential steps that need to be carried out with care and precision. It begins with creating a freight order, followed by adding a shipment order, and providing the package details. The next step is creating a freight route, which helps in tracking the shipment accurately.

View More